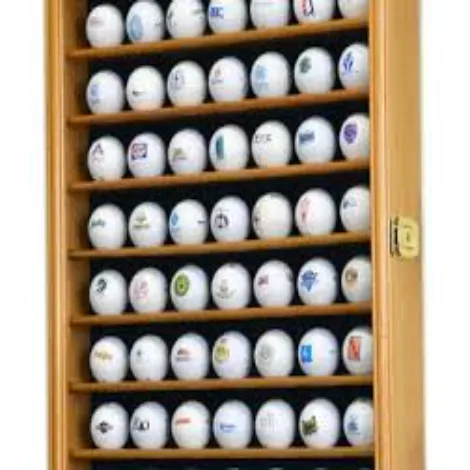

golf ball display box

Showcase your game in style.

Whether you’re preserving a hole-in-one moment or selling premium sports gear, our golf ball display boxes combine protection with presentation. At Custom Boxes Lab, we design boxes that turn golf balls into collectibles.

Availability: In Stock

Get Instant Quote

Designed to Impress

Our display boxes aren’t just containers—they’re keepsakes.

- Sleek design for modern or classic aesthetics

- Perfect for single balls, pairs, or full sets

- Great for gifts, awards, and retail packaging

Materials That Matter

We craft every box to protect and highlight your prized golf balls.

- Rigid board for durability and a premium feel

- Clear PVC or acrylic windows to spotlight the ball

- Foam or velvet inserts to hold balls securely in place

- Optional magnetic closure for a high-end touch

Custom Features

Tailor every detail to match your brand or personal story.

- Embossed or foil-stamped logos

- Custom printed lids or inside flaps

- Spot UV for added shine

- Die-cut windows in any shape

Add-Ons to Elevate the Experience

Make your golf ball box stand out from the crowd.

- Insert cards with score details or personal messages

- Soft-touch or leatherette finishes

- Gold foil text for tournament or corporate branding

- Compartments for tees or mini trophies

The 3Ps of Our Golf Ball Display Boxes

Presentation

Highlight each ball like a trophy with clear, refined packaging.

Protection

Keep memorabilia safe from scratches, dust, or damage.

Personalization

From one-off gifts to branded merchandise, we make it yours.

Why Custom Boxes Lab

Trusted by golf clubs, sports retailers, and event organizers.

- Low MOQ and bulk pricing

- Fast production & delivery

- Top-tier print and material quality

- Free custom design support

Ready to Tee Off in Style?

Get your custom golf ball display boxes today and put your prized shot—or product—on full display.

Custom Boxes Lab: because great moments deserve to be seen.

| Dimensions | All Custom Boxes & Shapes, Paper Bags, Mylar Bags, Tube Packaging |

| Availability | InStock |

| Printing | No Printing, CMYK, CMYK + 1 PMS Color, CMYK + 2 PMS Colors |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E flute Corrugated, Bux Board, Cardstock, Mylar, Paper Bag Stock, Tube Paper, Bespoke Packaging Materials |

| Quantities | No Minimum Order Required |

| Coating | Gloss, Matte, Spot UV, Holographic Foiling, Gold Foiling, Embossing, Silver Foiling, Debossing |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet, Bespoke Die-Cuts |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turn Around Time | 7-10 Business Days, Rush Available |

When measuring a custom box, there are a few technical specifications that must be considered to ensure proper design, manufacturing, and fit for the product. Here are the major technical things to measure a custom box:

Inside Dimensions (Critical for Product Fit)

- Length (L): The longest side of the box measured inside from one corner to the opposite corner.

- Width (W): The shorter side of the box measured inside perpendicular to the length.

- Depth/Height (D or H): Measured inside from the bottom to the top opening of the box. Always specify that dimensions are given in Length × Width × Height.

Outside Dimensions (Important for Shipping & Storage)

- Measure the outer surfaces of the box including material thickness.

- Outside measurements are used for pallet stacking, warehouse spacing, and shipping compliance.

Material Thickness (Board Caliper)

- The thickness of the packaging material (e.g., corrugated board, rigid stock, cardstock).

- Impacts both the internal usable space and external dimensions.

Flap Measurements

- For boxes with flaps (e.g., mailer or shipping boxes), measure:

- Inner flaps: Ensure they meet in the middle without overlapping too much.

- Outer flaps: Allow proper sealing without gaps.

Tolerances

- Account for manufacturing tolerances (usually ±1/16" or ±2mm depending on material).

- Ensure the product fits without being too tight or loose.

Volume Capacity

- Calculate internal cubic capacity (L × W × H).

- Helps in determining how much space the product will occupy and shipping efficiency.

Product Orientation

- Decide how the product sits inside the box and measure accordingly.

- Orientation affects whether length or width is the primary dimension.

Die-Cut Openings or Windows

- Measure exact placement, height, and width for any cutouts.

- Ensure structural integrity when adding windows.

Printing Bleed & Safe Zones

- Include measurements for:

- Bleed area: Extra space beyond the cut line for printing.

- Safe zone: Inner area where critical text or logos should be placed.

Closure Type & Locking Tabs

- Measure slots, tabs, or locks for boxes with custom closures.

- Precision is required to avoid misalignment during assembly.

Packaging Style

- Folds, creases, and scores must be measured for accurate dieline creation.

- Different styles (e.g., RSC, tuck-end, mailer, sleeve) require specific panel measurements.

Delivering Premium Packaging. Materials Tailored for Your Brand and Product.

Cardboard

Giving cardboard material option to give versatility and durability to your box, widely used in many industries.

Kraft

Offering eco-friendly kraft material for your product with the least environmental impact and minimizing waste.

Rigid

Offering you premium rigid boxes, perfect for luxury packaging and high-end presentation.

Corrugated

Custom Boxes Lab specializes in strong, reliable corrugated boxes ideal for shipping and storage.