Product Mailer Box

Looking for packaging that protects and impresses at the same time? Our product mailer boxes are designed for direct shipping and unboxing experiences, combining sturdy construction with aesthetic appeal. Ideal for subscription services, promotional kits, and retail orders, these boxes deliver a strong brand presence right at your customer’s door.

Availability: In Stock

Get Instant Quote

Designed To Fit Your Vision

We offer complete flexibility in box design, allowing you to create packaging that matches your product type, delivery method, and visual identity.

Materials

- Corrugated – reliable and shipping-ready

- Kraft – eco-friendly and naturally textured

- Cardstock – for lightweight or promotional items

- Rigid – premium feel for high-end mailers

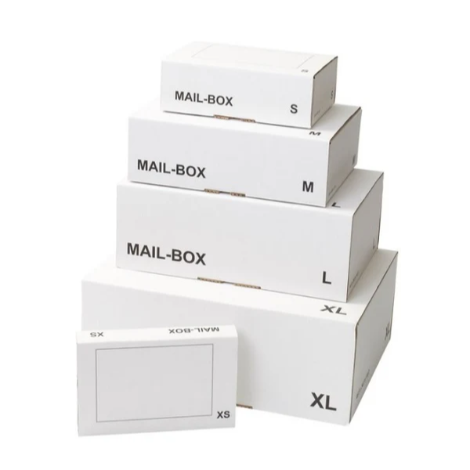

Sizes

Tailored sizes to fit everything from small accessories to large kits.

Prints

Printed with fade-resistant, chemical-free inks using CMYK, offset, or digital processes.

Add-ons

Choose protective fillers, branded sleeves, magnetic closures, or tissue wraps.

Types Of Boxes

We offer a variety of mailer styles for different product categories:

- Roll end tuck top mailers

- Front lock mailers

- Magnetic flap mailers

- Die-cut retail mailers

- Eco-pack subscription boxes

3Ps Approach

Our mailer boxes uphold the core pillars of effective packaging: presentation, preservation, and protection.

Presentation

Crisp printing and smooth finishes provide an elevated customer experience from the moment they open the box.

Preservation

Optional inner linings or custom inserts shield items from friction and environmental exposure.

Protection

Built to endure delivery stress, our mailers ensure your product reaches the customer intact and undamaged.

Upgrade To Premium Packaging

Enhance your brand value with upscale finish options, such as:

- Matte or gloss lamination

- Embossing or debossing

- Metallic foil stamping

- Spot UV highlights

- Soft-touch coatings

Why Choose Us?

We combine strength and style to create mailer boxes that enhance both product safety and brand storytelling. With flexible options, sustainable materials, and expert support, our packaging adapts to your business needs. You also benefit from:

- Fast turnarounds

- Low order quantities

- Recyclable materials

- Support from packaging professionals

Get A Quote

Contact us today to create your ideal product mailer box with features that elevate your packaging game.

| Dimensions | All Custom Boxes & Shapes, Paper Bags, Mylar Bags, Tube Packaging |

| Availability | InStock |

| Printing | No Printing, CMYK, CMYK + 1 PMS Color, CMYK + 2 PMS Colors |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E flute Corrugated, Bux Board, Cardstock, Mylar, Paper Bag Stock, Tube Paper, Bespoke Packaging Materials |

| Quantities | No Minimum Order Required |

| Coating | Gloss, Matte, Spot UV, Holographic Foiling, Gold Foiling, Embossing, Silver Foiling, Debossing |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet, Bespoke Die-Cuts |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turn Around Time | 7-10 Business Days, Rush Available |

When measuring a custom box, there are a few technical specifications that must be considered to ensure proper design, manufacturing, and fit for the product. Here are the major technical things to measure a custom box:

Inside Dimensions (Critical for Product Fit)

- Length (L): The longest side of the box measured inside from one corner to the opposite corner.

- Width (W): The shorter side of the box measured inside perpendicular to the length.

- Depth/Height (D or H): Measured inside from the bottom to the top opening of the box. Always specify that dimensions are given in Length × Width × Height.

Outside Dimensions (Important for Shipping & Storage)

- Measure the outer surfaces of the box including material thickness.

- Outside measurements are used for pallet stacking, warehouse spacing, and shipping compliance.

Material Thickness (Board Caliper)

- The thickness of the packaging material (e.g., corrugated board, rigid stock, cardstock).

- Impacts both the internal usable space and external dimensions.

Flap Measurements

- For boxes with flaps (e.g., mailer or shipping boxes), measure:

- Inner flaps: Ensure they meet in the middle without overlapping too much.

- Outer flaps: Allow proper sealing without gaps.

Tolerances

- Account for manufacturing tolerances (usually ±1/16" or ±2mm depending on material).

- Ensure the product fits without being too tight or loose.

Volume Capacity

- Calculate internal cubic capacity (L × W × H).

- Helps in determining how much space the product will occupy and shipping efficiency.

Product Orientation

- Decide how the product sits inside the box and measure accordingly.

- Orientation affects whether length or width is the primary dimension.

Die-Cut Openings or Windows

- Measure exact placement, height, and width for any cutouts.

- Ensure structural integrity when adding windows.

Printing Bleed & Safe Zones

- Include measurements for:

- Bleed area: Extra space beyond the cut line for printing.

- Safe zone: Inner area where critical text or logos should be placed.

Closure Type & Locking Tabs

- Measure slots, tabs, or locks for boxes with custom closures.

- Precision is required to avoid misalignment during assembly.

Packaging Style

- Folds, creases, and scores must be measured for accurate dieline creation.

- Different styles (e.g., RSC, tuck-end, mailer, sleeve) require specific panel measurements.

Delivering Premium Packaging. Materials Tailored for Your Brand and Product.

Cardboard

Giving cardboard material option to give versatility and durability to your box, widely used in many industries.

Kraft

Offering eco-friendly kraft material for your product with the least environmental impact and minimizing waste.

Rigid

Offering you premium rigid boxes, perfect for luxury packaging and high-end presentation.

Corrugated

Custom Boxes Lab specializes in strong, reliable corrugated boxes ideal for shipping and storage.